- +61 7 3374 2877

- Email Us

Excessive temperature rise within switchgear is a leading cause of catastrophic failures and reduced lifespan of critical assets. This article explores the root causes of temperature rise and examines the engineering strategies employed in switchgear design to mitigate failure risks, improve safe operation and extend operational life.

In modern electrical systems, low voltage switchgear plays a vital role in ensuring safe and efficient power distribution. Operating typically below 1000 V AC and 1500 V DC, these systems are central to managing and protecting electrical circuits in commercial and industrial environments. However, one of the most critical and often underestimated factors in switchgear design is thermal performance.

Why Switchgear Gets Hot

One critical issue that needs to be addressed in the operation of low voltage switchgears is the phenomenon of heat generation. Heat generation in switchgear is inevitable. The primary source is Ohmic losses, where electrical resistance in conductors converts energy into heat. This effect is more pronounced in Alternating Current (AC) systems due to phenomena like the skin effect, which causes current to concentrate near the conductor’s surface, increasing resistance and heat. In contrast, Direct Current (DC) systems distribute current more evenly, resulting in lower thermal stress.

Beyond Ohmic losses, eddy currents in nearby metallic components and power losses in internal devices (like circuit breakers and relays) also contribute to heat buildup. If unmanaged, this heat can degrade performance, reduce efficiency, and even pose safety risks.

Why Thermal Management Matters

High temperatures can have several destructive effects on switchgear:

That’s why thermal limits are strictly defined in IEC 61439 standard, which mandates rigorous testing to ensure safe operating temperatures. Following IEC 61439 standard not only ensures compliance but also contributes to the overall performance and safety of the electrical installation.

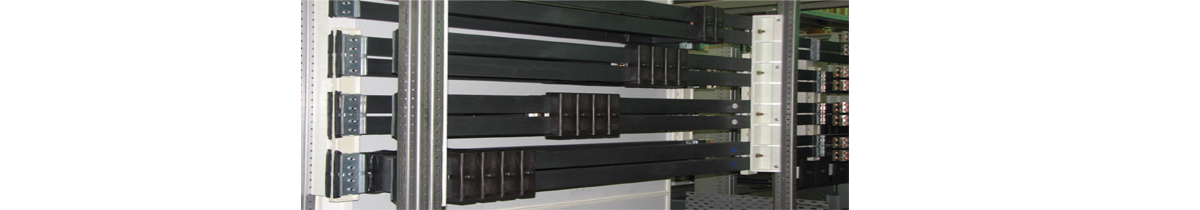

Engineering for Thermal Excellence: ABB MNS3.0 System

ABB’s MNS3.0 Low Voltage Switchgear exemplifies how thoughtful engineering can overcome thermal challenges. The system is designed with a deep understanding of the physics behind heat generation and dissipation and engineered to adhere to the standardised limits, ensuring it meets and exceeds the stipulated IEC 61439 requirements. For example, surface temperature.