- +61 7 3374 2877

- Email Us

This is a continuation of a series of articles about overhead line conductors which have been presented in recent issues of APT’s T&D Magazine. The previous subjects have been on general overhead line design & conductors; permanent conductor elongation; general change of state equations; conductor parameters; conductor fatigue; conductor annealing, steady state & transient conductor current ratings, conductor corona and conductor corrosion. This article will discuss bare aluminium conductor types and selection.

Conventional conductors are conductors with maximum operating temperatures for extended periods for ACSR AAC and AAAC about 100°C and for SC/GZ about 50°C. Non-conventional conductors operate at temperatures for extended periods greater than 100°C. A special feature article will be presented in the next issue on “innovative” nonconventional specialised conductors.

The Ideal Conductor

Conductor selection is a balanced between the electrical

conductivity and the mechanical strength. An understanding of ideal conductor properties is helpful in the selection and design of a practical conductor. Perhaps an ideal conductor would have the following properties,

When designing or selecting practical conductors, the designer is essentially compromising each of the ideal conductor parameters for a particular application.

Bare Overhead Conductor Types & Standards

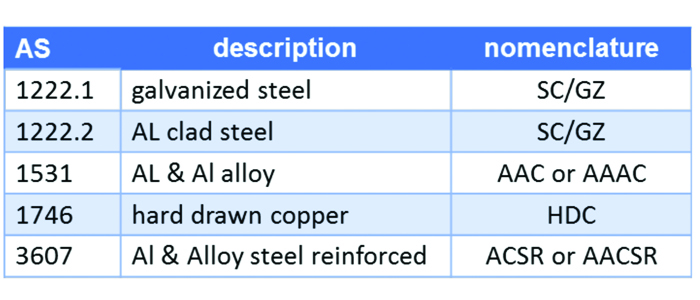

Bare overhead conductor types and the associated Australian Standard are shown in Table 1.

The basis of the AS conductors is conductors constructed from a range of standard wire diameters which results in a range of varying total electrical csa. Differing alloys and reinforcing are used for differing conductivity, sag and strength options.

Aluminium and Aluminium Alloy

A number of different high strength aluminium alloys have been developed to achieve the balance between electrical conductivity and mechanical strength. Besides electrical grade 1350 aluminium, two alloys 1120 and 6201A have found wide acceptance for overhead conductors.

Aluminium 1350 is essentially unalloyed aluminium with the highest commercial purity and is widely used for a range of

electrical applications. The aluminium wires in AAC and “conventional” ACSR are manufactured from 1350 aluminium. This grade of aluminium has previously been known as EC, IS and

by the alloy designations 1045 and 1445. The minimum aluminium content is 99.50% and the high electrical conductivity is achieved

by strict control of trace impurities.

Alloy 6201A is aluminium alloy containing small additions of silicon and magnesium which achieves high strength by a combination of cold working and precipitation hardening under appropriate heat treatment. Alloys of this type have been developed in a number of countries and have been previously know by various trade names such as Silmalec (UK), Aldrey (Germany, Switzerland), Arvidal (Canada), Almelec (France) and Kemsalex (Australia). The nominal chemical composition of 6201 alloy is Si – 0.6%, Mg – 0.7% and the remainder Al.

Alloy 1120 is a relatively high purity aluminium alloy, containing small additions of copper and magnesium, does not require any heat treatment and achieves it strength solely by cold working. Alloys of this type have been previously known as AL59, Ductalex and NHTC (non heat treated conductor). The nominal chemical composition of 1120 alloy is Cu – 0.2%, Mg – 0.06% and Al – 99.20% min. The optimum electrical properties are achieved by the strict control of trace impurities.